Thermal management in high power LEDs is a crucial consideration as LED technology increasingly powers residential, commercial, and industrial lighting. From homeowners upgrading to bright floodlights to engineers designing large-scale installations, temperature control directly impacts LED performance and lifespan. High-output LEDs generate heat at the semiconductor junction; without efficient thermal management, light output deteriorates, fixture longevity suffers, and safety can be compromised. Whether you’re illuminating a kitchen with recessed downlights or equipping a warehouse with high-bay fixtures, understanding LED thermal behavior is essential for long-term lighting success.

Why Thermal Management in High Power LEDs Matters

At the heart of every LED is a semiconductor junction that emits light—but heat is a byproduct. Although LEDs are far more efficient than halogen or incandescent bulbs, high-power models (10W to 50W or 800 to 5,000 lumens) can still generate significant heat. Without adequate thermal management in high power LEDs, elevated junction temperatures can reduce luminous output, shift color rendering, and trigger early component failures.

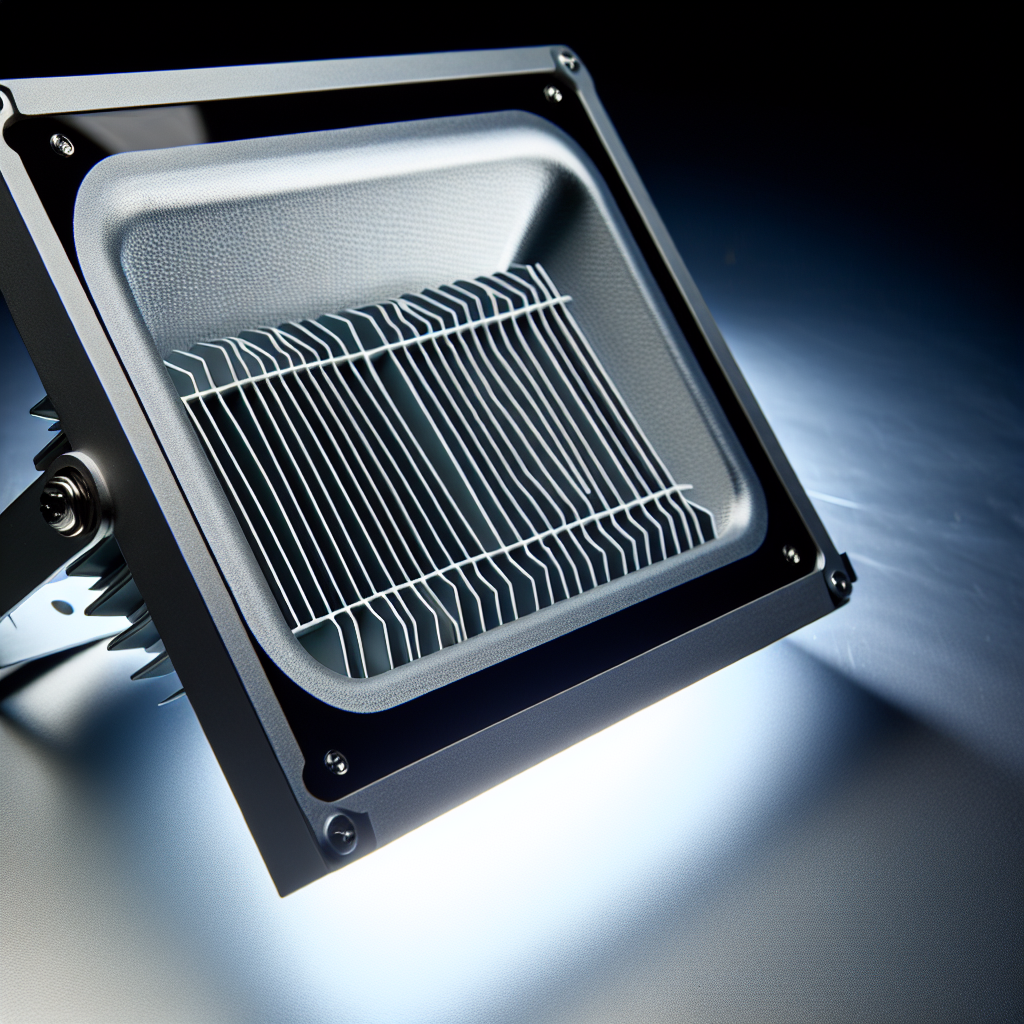

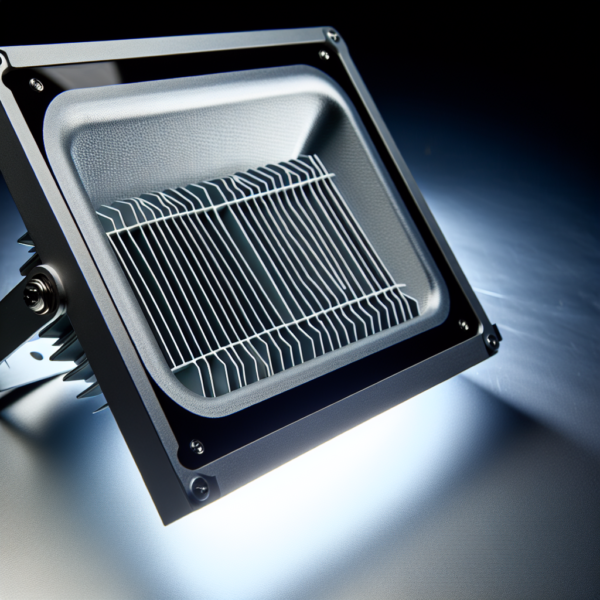

Efficient thermal regulation moves heat from the LED die to the surrounding environment. Outdoor LED floodlights, often outputting 3,000 to 5,000 lumens, utilize finned aluminum heatsinks to dissipate heat. In kitchens, 7-inch recessed downlights operating at 15W benefit from heat-spreading materials that prevent trim discoloration and housing warping. Products claiming lifespans of 25,000 to 50,000 hours depend on stable thermal profiles to deliver on those promises.

Common Methods of Managing Heat in High-Power LED Fixtures

Various thermal solutions are used depending on the fixture’s wattage, environment, and form factor. Understanding these methods empowers better buying and installation decisions when evaluating thermal management in high power LEDs:

- Passive Cooling: Ideal for open-air or ventilated fixtures, large aluminum heatsinks radiate heat away naturally. Applications include troffers, soffit lights, and pendant fixtures.

- Active Cooling: High-wattage commercial lights, such as 100W+ high-bays producing over 12,000 lumens, often use fans or liquid systems. These require more maintenance but excel in tight or sealed spaces.

- Thermal Interface Materials (TIMs): Thermal pastes or pads ensure efficient heat transfer between the LED board and heatsink. These are critical in compact fixtures like track lights and spotlights.

- Advanced Fixture Design: High-end fixtures include magnesium alloy housings, copper-core PCBs, and ceramic substrates to enhance heat dissipation. LED strip lights often feature aluminum extrusion channels for passive cooling.

Products undergoing standardized thermal testing (e.g., LM-80, TM-21) offer the best reliability. For example, 4,000K flush-mount ceiling lights rated for enclosed use should list actual thermal performance metrics. In sealed commercial luminaires using T8 LED tubes, choose models with integrated drivers and thermal cutoff protections.

Lighting Scenarios Where Thermal Management Is Critical

As wattage and density increase, so does the need for effective thermal management in high power LEDs. The following applications underscore where heat control makes the biggest impact:

- Garage and Workshop Fixtures: Bright, overhead fixtures often emit 5,000+ lumens and operate in semi-enclosed areas. Choose designs with vented metal casings and generous heatsinks.

- Recessed Lighting in Kitchens and Baths: Often set in insulated ceilings, these fixtures risk heat buildup. Look for IC-rated units that support enclosed or semi-enclosed operation with thermal protection features.

- LED Grow Lights: Operating for extended periods with outputs of 100W–400W+, they require high-efficiency cooling—often active fans or water cooling plates—to remain stable.

- Outdoor Flood and Spotlights: These must withstand temperature fluctuations and seasonal heat loads. High-output models incorporate passive cooling plus thermal expansion gaps.

- Gallery Track and Accent Lighting: Fixtures with narrow beams and high CRI create localized heat. Ceramic heat spreaders, temperature sensors, and thermal dimming help prevent overheating.

Even in decorative settings such as multi-bulb chandeliers using 5–7W filament LEDs, heat can accumulate in tightly enclosed ceiling fixtures. If using globes or flush mounts in closets or entryways, ensure bulbs are rated for enclosed environments.

Installation Tips for Better Thermal Control

Proper installation is as vital as product design. To ensure the best possible thermal management in high power LEDs, follow these best practices:

- Maintain Airflow: Avoid snug installations. Attic-mounted recessed LEDs must not come into direct contact with insulation unless IC-rated cans are specified.

- Use Compatible Dimmers: Incorrect dimmers can cause heat-inducing voltage irregularities. Prefer ELV or TRIAC dimmers compatible with your LEDs.

- Select Rated Bulbs for Enclosures: Bulbs not designed for enclosed spaces can overheat and fail. Always check for “enclosed fixture rated” labels.

- Optimize Fixture Spacing: In designs with puck or strip lights under cabinetry, leave gaps for air to flow freely. Avoid crowding isolated heat points.

- Respect Ambient Temp Limits: High-power LEDs list max operating temperatures (e.g., 50°C). Never install under metal covers or confined soffits that trap heat.

For DIY garage upgrades, linear LED shop lights with metal frames and side-venting perform better than plastic-bodied alternatives. Even with matching lumens, those without thermal design considerations degrade faster and generate unwanted discoloration or warping.

How to Choose Thermally Optimized LED Fixtures

Choosing LED products built with thermal management in mind helps extend service life and deliver consistent brightness. Look for these key indicators of smart thermal design when evaluating high-power options:

- Lifespan Ratings: Seek out products with LM-80 and TM-21 test results—like “L70: 50,000 hours”—which show how long lights maintain output before declining.

- Metal Construction: LED boards with copper cores and housings built from anodized aluminum dissipate heat better than plastic-bodied alternatives.

- Integrated Temperature Sensors: Smart downlights may include thermal sensors that reduce output safely under heavy loads, protecting internal components.

- Modular Power Supplies: Lights with external drivers or power components reduce heat stress at the LED level, boosting efficiency and reducing risk.

- Enclosure Compatibility: For domed, flush-mount, or recessed retrofit applications, confirm that both bulb and driver are tested for enclosed environments.

For projects pursuing LEED credits or ENERGY STAR labeling, prioritizing thermal management in high power LEDs contributes to sustainability goals. Products that avoid thermal failure last longer, consume less energy over time, and reduce replacement waste—key markers of energy-efficient design.

Lighting Design Meets Thermal Strategy

Great lighting isn’t just about brightness and placement—it’s also about thermal integrity. Designers integrating high-output lighting into modern homes, commercial spaces, or creative installations must align layout with effective heat control strategies. Plan fixture spacing, use purpose-built dimmers, and specify products with proven thermal certifications to create lighting systems that last, perform, and stay cool no matter the setting.