Proper LED lighting for loading docks plays a vital role in maintaining workplace safety, operational efficiency, and energy savings. Loading docks are high-traffic, high-risk areas where workers, forklifts, and trucks interact daily—often under tight deadlines and in challenging conditions. Poor lighting can increase the risk of accidents, reduce productivity, and create costly inefficiencies.

With advancements in LED technology, facility managers now have better options than ever for lighting these critical spaces. This guide offers expert advice on selecting the right LED lighting for loading docks, covering safety, design, cost, and performance considerations.

Why LED Lighting Is Ideal for Loading Docks

Traditional lighting sources like metal halide, high-pressure sodium, or fluorescent fixtures are quickly becoming outdated due to their high energy consumption, short lifespan, and poor performance in harsh environments.

LEDs, by contrast, offer:

-

Superior brightness and visibility

-

Longer lifespan (50,000–100,000 hours)

-

Instant-on performance, with no warm-up time

-

Resistance to vibration, cold, and moisture

-

Significant energy savings over time

Whether you’re retrofitting an existing facility or planning a new installation, LEDs offer unmatched value and reliability for dock lighting.

Prioritize Safety with High Visibility

Loading docks are dangerous by nature. Workers are exposed to moving trucks, forklifts, heavy cargo, and sometimes wet or uneven surfaces. Inadequate lighting increases the chance of accidents, injuries, and costly downtime.

When designing a lighting plan for loading docks:

-

Use high-lumen LED fixtures to ensure ample brightness for visibility.

-

Select fixtures with a high Color Rendering Index (CRI)—above 80—to accurately reveal color contrasts, signage, and surface conditions.

-

Ensure uniform light distribution to eliminate dark corners and harsh shadows.

-

Install motion sensors or occupancy controls to activate lighting during loading and unloading activity, especially in low-traffic or semi-enclosed dock bays.

Pro Tip: Use directional lighting like adjustable dock arms or gooseneck dock lights to illuminate trailer interiors, where shadows can be particularly dangerous.

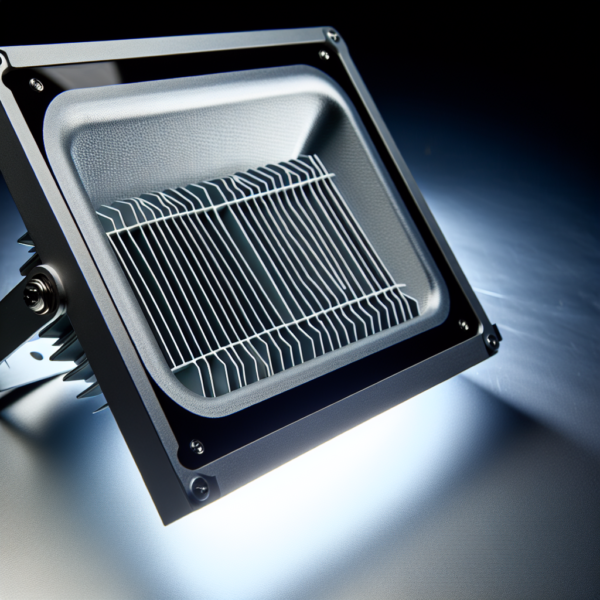

Use Durable Fixtures Designed for Tough Environments

Loading docks face harsh and variable conditions, including:

-

Extreme temperatures

-

High humidity

-

Dust and debris

-

Vibration from nearby equipment

To withstand these factors, choose IP65 or higher-rated LED fixtures that are sealed against dust and water ingress. Look for industrial-grade housings made from aluminum or polycarbonate with shatterproof lenses. These fixtures will last longer and require less maintenance, even in challenging settings.

Dock areas also benefit from impact-resistant designs that can survive accidental bumps from forklifts or pallet jacks.

Incorporate Energy Efficiency and Cost Control

One of the greatest advantages of LED lighting for loading docks is its ability to significantly reduce energy consumption—often by 50% or more compared to legacy systems.

Additional cost-saving strategies include:

-

Dimming controls that adjust brightness levels based on time of day or task

-

Daylight harvesting sensors for facilities with skylights or translucent panels

-

Networked lighting systems that centralize monitoring and scheduling across multiple dock areas

Investing in energy-efficient lighting may also qualify your business for utility rebates or tax incentives, depending on your local jurisdiction and energy provider.

Design for Visibility Without Glare

While brightness is important, too much light or poorly aimed fixtures can cause glare, which is just as hazardous as darkness. Glare can impair vision, reduce reaction time, and create unsafe conditions.

To manage this:

-

Use fixtures with glare shields, diffusers, or frosted lenses

-

Position lights to avoid direct lines of sight into drivers’ or workers’ eyes

-

Adjust beam angles to direct light where it’s needed—on work zones and inside trailers—not across empty space

For open-air loading docks, consider cutoff optics that minimize light spill and comply with local light pollution guidelines.

Choose the Right Fixture Types

Each area of the dock requires tailored lighting solutions. Here are some common LED options for different loading dock zones:

-

Wall Packs: Mounted on the building exterior, ideal for perimeter lighting and general dock visibility

-

Dock Arm Lights / Gooseneck Lights: Flexible fixtures that shine directly into trailers for cargo inspection and safe unloading

-

Canopy or High Bay Lights: Perfect for covered docks or loading bays with higher ceilings

-

Pole-Mounted Area Lights: Provide broader coverage for truck courts, staging areas, and yard access

Selecting the right mix of these fixtures ensures your entire loading zone is safely and efficiently lit.

Plan for Long-Term Maintenance and ROI

While LEDs have a higher upfront cost than traditional fixtures, the return on investment (ROI) is substantial. Reduced energy bills, minimal maintenance, and fewer replacements mean LEDs pay for themselves quickly—often in less than two years.

To maximize your ROI:

-

Choose LEDs with a minimum five-year warranty

-

Opt for easy-to-service designs or modular components

-

Keep a basic maintenance schedule to clean lenses and check wiring

Also, factor in downtime: fewer bulb failures means fewer disruptions to shipping and receiving operations.

A Smarter Approach to Dock Safety and Efficiency

The right LED lighting for loading docks does more than just brighten the space—it improves safety, increases productivity, and reduces costs. By focusing on the specific needs of your facility and investing in durable, high-performing fixtures, you can create a safer and more efficient environment for your workers, drivers, and delivery partners.

Whether you’re upgrading an old system or designing from the ground up, following best practices in LED lighting will keep your loading docks operating smoothly—and your bottom line in check.