LED lighting has redefined the standard for energy-efficient illumination. By producing high-intensity light with far less energy consumption than incandescent or fluorescent bulbs, LEDs have become the leading choice for residential, commercial, and industrial applications. But with this innovation comes a new challenge: managing heat—not from the light source, but from the electronics that power it. Central to solving this challenge is the heat sink in LED fixtures, a critical component that ensures longevity, performance, and safety. In this guide, we’ll explore the role of heat sinks, how they work, and the cutting-edge engineering behind today’s most advanced thermal management solutions.

Why Heat Sinks Matter in LED Fixtures

At first glance, LED lights might not seem to need cooling. After all, they’re cool to the touch compared to glowing-hot incandescent bulbs. But the real source of heat in an LED system isn’t the light-emitting diode itself—it’s the semiconductor junction and driver circuitry that power the LED.

Even with the best LED efficiency ratings (sometimes reaching 45% light conversion), more than half of the electrical energy is still converted into heat. If that heat is not managed properly, it can degrade the LED’s materials, shorten its lifespan, reduce brightness, and shift the light color over time.

That’s where the heat sink in LED fixtures plays a pivotal role. It prevents thermal buildup by pulling heat away from sensitive components and dissipating it into the surrounding environment.

How Heat Sinks Work: Conduction Meets Convection

A heat sink operates on two main principles: conduction and convection.

-

Conduction is the process of transferring heat from the LED’s semiconductor chip into the heat sink. This requires direct physical contact and a thermally conductive pathway with minimal resistance.

-

Convection is the release of that heat into the air surrounding the fixture. This depends on the design and surface area of the heat sink, which allows air to flow around it and carry heat away.

The effectiveness of a heat sink in LED fixtures depends on optimizing both processes.

Improving Conduction: Materials and Bonding

The first challenge in any heat sink design is ensuring efficient contact between the LED chip and the heat sink. Without a proper bond, heat will be trapped at the junction, leading to performance degradation.

To improve conduction:

-

Thermal Interface Materials (TIMs) are used between the LED and the heat sink to eliminate air gaps and improve conductivity. High-end LEDs may use thermal pastes, pads, or proprietary bonding compounds.

-

Aluminum is the most common material used for heat sinks due to its excellent thermal conductivity, low cost, and ease of shaping.

-

In premium applications, copper may be used for its superior heat conduction, although it’s heavier and more expensive.

Some manufacturers have developed proprietary thermal bonding technologies that ensure better contact between components, further reducing thermal resistance and improving overall system efficiency.

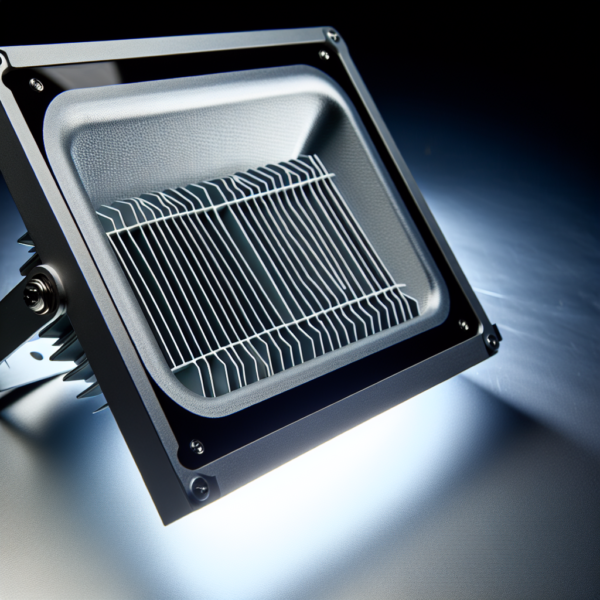

Optimizing Convection: Surface Area and Fin Design

Once heat enters the heat sink, it must be released into the surrounding air as efficiently as possible. To do this, heat sinks are designed with fins or ridges that increase surface area—allowing more air contact and better cooling.

Innovative approaches include:

-

Double-folded fins for maximum surface exposure

-

Aerodynamic fin geometry to direct air over the most thermally active areas

-

Vertical heat flow orientation to take advantage of the natural rise of warm air (passive convection)

-

Low-profile heat sinks for applications where space is limited but heat still needs to be managed effectively

Some manufacturers even tailor fin designs based on fixture mounting orientation—whether wall-mounted, ceiling-hung, or integrated into recessed housings—to optimize airflow.

Passive vs. Active Cooling in LED Fixtures

Most LED lighting relies on passive cooling, which uses no moving parts and instead depends on well-designed heat sinks and natural airflow.

Active cooling, such as small fans or liquid cooling systems, is reserved for high-output LED fixtures—like theatrical, broadcast, or stadium lighting—where passive solutions alone aren’t sufficient.

Passive systems are preferred in architectural and commercial settings due to their silent operation, lower maintenance, and greater reliability.

Smart Integration: The Future of LED Heat Sink Design

Today’s top-tier LED fixture manufacturers are moving beyond standard heat sinks. They’re designing integrated systems where the entire fixture—housing, optics, and electronics—is developed with thermal management in mind.

New trends include:

-

Smart thermal sensors that adjust light output based on fixture temperature

-

Modular heat sinks that can be replaced or scaled based on fixture size

-

Hybrid materials that combine thermal conductivity with corrosion resistance for extreme environments

Why Heat Sink Design Matters

The heat sink in LED fixtures is not just a support component—it’s a core part of what makes LED lighting systems effective, durable, and efficient. Without good thermal management:

-

LEDs lose brightness and efficiency over time

-

Color rendering becomes inconsistent

-

Fixtures fail sooner than expected

But with a well-designed heat sink, LED lights can deliver up to 100,000 hours of consistent performance, making them a smart, long-term investment for everything from retail spaces and offices to warehouses and industrial plants.

Choosing Fixtures With Proper Thermal Design

When evaluating LED fixtures for your next project, don’t just focus on lumen output or CRI. Pay attention to thermal design:

-

Does the manufacturer mention heat sink materials and specs?

-

Are the fixtures rated for continuous operation in warm environments?

-

Is there mention of passive or active thermal management?

A well-designed heat sink in LED fixtures ensures you get the performance and longevity you’re paying for. It’s the silent partner in your lighting system—keeping your LEDs running cooler, brighter, and longer.